Pipeline Coatings Cathodic disbonding testing

Protective coatings are applied to buried or immersed metallic structures thus providing a primary line of defence against corrosion and is usually used in conjunction with Cathodic protection. To test the coatings ability to prevent corrosion attack a cathodic disbonding test is used.

This cathodic disbonding test method determines the resistance to cathodic disbonding of a coating system between coating and steel substrate, resulting in loss of coating adhesion.

AS4352-2005 Test Cell A

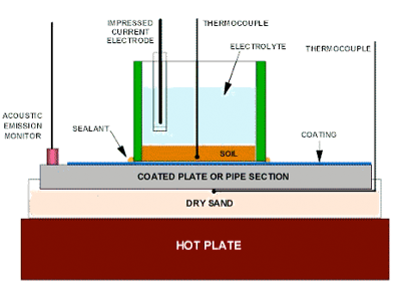

LMATS performs cathodic disbonding test in accordance to AS 4352-2005. Cathodic Disbondment Test is a test method to evaluate the long-term performance of coatings used for protecting metal pipes and pipelines being installed into underground environments. The Cathodic Disbondment Test is a well-known and generally accepted laboratory testing procedure for pipeline coatings.

In this test, an intentional defect (holiday) on a coated panel or section of the coating to be tested is immersed in a saline solution contained in a test cell and cathodic protection is applied. After a specified period, the panel is examined for evidence of coating disbondment around the intentional defect and if present, the radial disbondment and disbonded area are determined.

A good cathodic disbonding test result (ie a small delamination radii) would indicate that the coating could be reasonably expected not to delaminate to a large extent in the presence of cathodic protection and a small coating damage with the steel surface exposed to the soil.

This makes cathodic disbonding testing an essential tool for the quality control of pipeline coatings and other equipment in a reactive environment.

Cathodic disbonding testing quality control applications

- Ships and boats

- Marine - jetties, harbors, offshore structures

- Bridge, Building, Dam Construction - Steel in concrete - concrete reinforcement, rebar coatings, Coated Steel Reinforcing Bars

- Galvanized steel - hot-dip galvanizing

- Pipelines constructed from steel

- Pipelines constructed from pre-stressed concrete

Contact LMATS for all your protective coating cathodic disbonding testing requirements