PAUT - Phased Array Ultrasonic testing is an advanced ultrasonics methods, known for its higher probability of detection and precise measurement capability. PAUT has many advantages over other traditional ultrasonic and radiograpahic test methods. It is Fast, Accurate, Traceable, Archivable.

Innovative Solutions

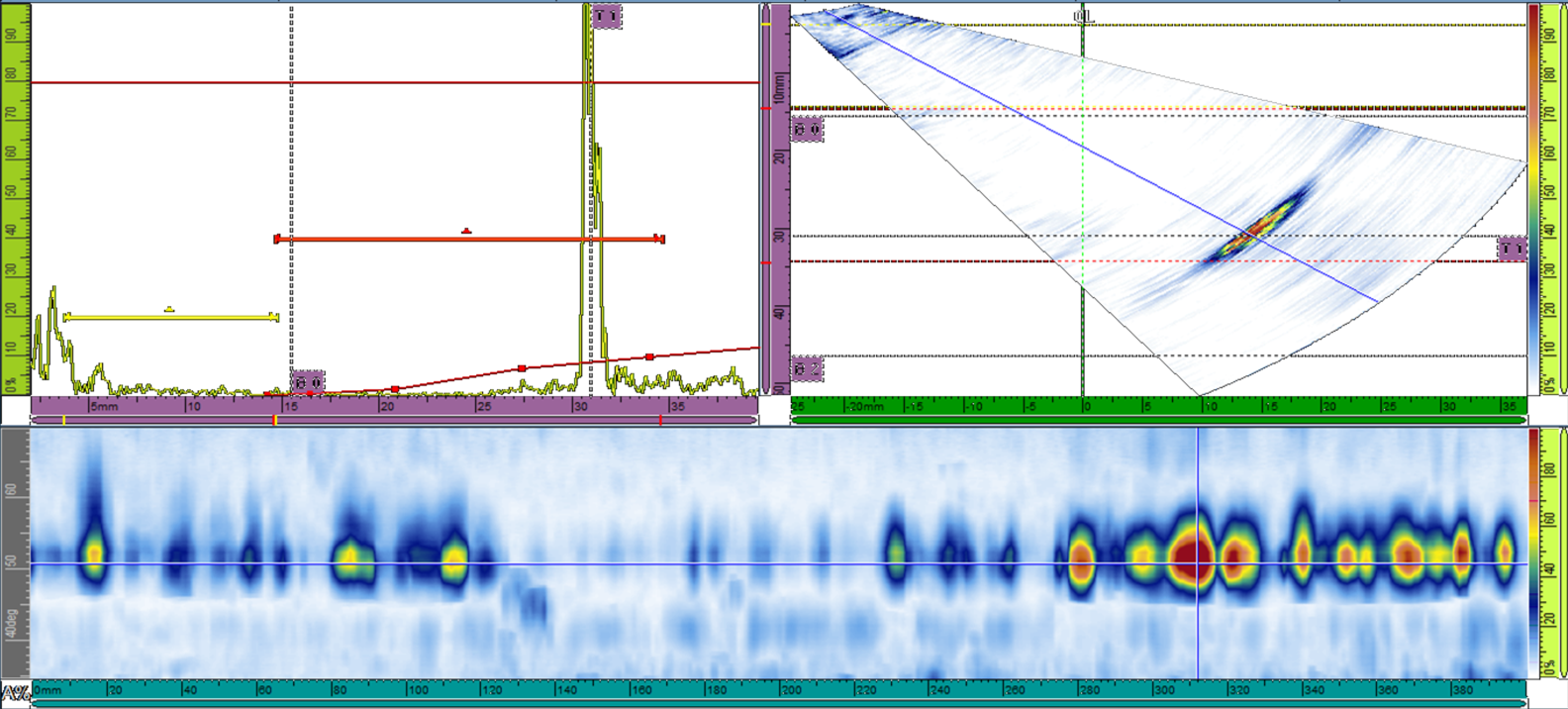

LMATS develops innovative PAUT solutions for compex shaped objects. The below photograph is a unit designed to examine over the painted exterior or mobile fuel transport tanks and detect anamolies on the internal surface. This saves significant cost by eliminating the need for emptying the tank, washing and confined space entry. The solution eliminated significnat downtime, improving productivity and reducing operational costs significantly for the client.

3D Corrosion Mapping Reports

LMATS Capabilities

- Corrosion mapping for thickness measurement in pressure vessels, pipes, tanks and structures.

- Defect assessmet of butt welds in pipes and pressure vessels and large structures, bifurcation lines, valve bodies and more.

- Scan complex geometries including painted cylindrical, trapezoidal fuel transport tankers.

- Customised development of qualification blocks, configuring rigs for data collection and levels of post-analysis reporting.

- 100% weld volume coverage at scanning intervals of 1mm, of high pressure and high temperature piping welds at power station sites using encoded scanning on circumferential and seam welds between 20mm to 75mm wall thickness.

- Inspection of small bore tubes - Internal diameter of down to 38mm; having a minimum wall thickness of 6mm.

- Inspection of complex geometry branch welds with variable weld profile using encoded scanning for accurate sizing of internal defects.

- Turbine and generator components inspections with special focus on areas of high stress concentration such as fur tree serrations of turbine blade roots and geometry changes along exciter cooling fans.

- Corrosion wastage in wind tower foundation bolts with reliable monitoring of corrosion wastage along the length of bolts up to 5 times its diameter.

- Transverse cracks in-situ in shafts, axles, spindles, hold down bolts.

- Pipeline welding, high-pressure vessels, bifurcation lines and valve bodies and provision of detailed analysis reports.

- Precise detection, measurement and reporting of smaller cracks for condition monitoring or repair.

- Aerospace CFRP (Composite Fibre Re-enforced Polymers) for delaminations and other discontinuities.

LMATS Personnel

Our PAUT experts have been involved in various research and development programs and have been pioneers in various techniques. LMATS ’s personnel have conducted literature reviews and published local conference papers of PAUT on compliance to Standards and the use of qualification blocks to increase the probability of detection. Research investigations have been conducted on the effects of PAUT signal responses to temperature, surface conditions and complaints beyond those prescribed in Standards. Specially designed calibration blocks were also fabricated for PAUT testing on different materials such as aluminium, stainless steel, low carbon steel and Inconel. Undertaking the research and development program has produced sound fundamentals for understanding the theory and practical aspects behind PAUT.

LMATS ’s personnel have experience performing PAUT inspections locally and overseas. They have vast experience in many industries ranging from power generation, mining, transport and petrochemical. LMATS ’s personnel are certified by AINDT, BINDT, TWI CSWIP Phased Array Level 2 and are competent at performing PAUT in these environments through regular safety training and inductions.

PAUT Limitations

PAUT has many applications, but can be inhibited by limitations such as geometry, time and access. In general, a scan plan is required as an initial step to ensure suitable beam coverage is achieved. LMATS ’s team of PAUT operators develop PAUT scan plans and offer technical justification summaries to account for test parameters.

Contact LMATS to discuss your requirements, via +61 3 9399 8145 or our online form.