What is Vibration Analysis?

Vibration Analysis is a non-destructive & predictive testing technique that has a wide range of applications. It can identify a forerunner to predict problems well in advance of breakdown before catastrophic failure occurs. This approach improves equipment reliability while eliminating the stress associated with reactive maintenance.

LMATS offers vibration analysis services to a wide range of industries and commercial clients.

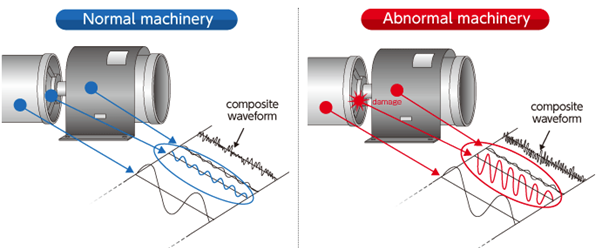

All machinery produces vibrations while running normally. Vibration monitoring technologies plot this as a waveform of amplitude over time. Spectrum analysis breaks this signal into individual frequencies, converting the data into a spectrum of frequency and amplitude. Our experts can search for abnormalities, using the information to calculate more detailed, specific data about the machine’s operating condition.

This examination can apply to many types of rotating equipment including, but not limited to:

- Turbines

- Electric motors

- Gearboxes

- Pumps

- Compressors

- Fans

- Conveyor

- Mills

- Mixers

Vibration analysis can identify a wide range of defects including, but are not limited to:

- Hydraulic defects like vane/flow faults, cavitation, and flow turbulence

- Induction motor defects such as cracked or broken rotor bars, stator eccentricity, rotor bow, loose stator winding, and soft foot.

- Bearing defects including pitting, cracking, oil whirl, oil whip, wear, fluting, skidding, races, balls, and cage damage.

- Gearbox defects e.g. tooth wear, tooth load, eccentric gears, misaligned gear, gear backlash, and cracked or broken teeth.

- Coupling defects in the form of imbalanced, wear, misaligned, and lock.

- Belt drive defects including worn belts, eccentric sheaves, belt resonance, and sheave misalignment.

Vibration Analysis Advantages

- Reduced maintenance workload

- Extended machinery life

- Increase reliability

- Reduce production downtime

- Reduce repairs and failures

- Reduce maintenance costs

LMATS offers to supplement your existing vibration or monitoring program or start from scratch by establishing monitoring frequencies, databases, and alarm limits, among other things. Our certified, experienced vibration analysts work to satisfy your facility’s specific needs. We aim to reduce costs while increasing uptime and efficiency. LMATS also performs balancing and alignment to keep client machinery running optimally.