Aluminium intergranular corrosion (NAMLT)

LMATS has been assessed by NATA, Australia to perform a Standard Test Method in accordance with ASTM G67 for Determining the Susceptibility to Intergranular Corrosion of 5XXX Series Aluminium Alloys by Mass Loss After Exposure to Nitric Acid (NAMLT Test). This test is also commonly referred to as Nitric Acid Mass Loss Test (NAMLT) in the industry.

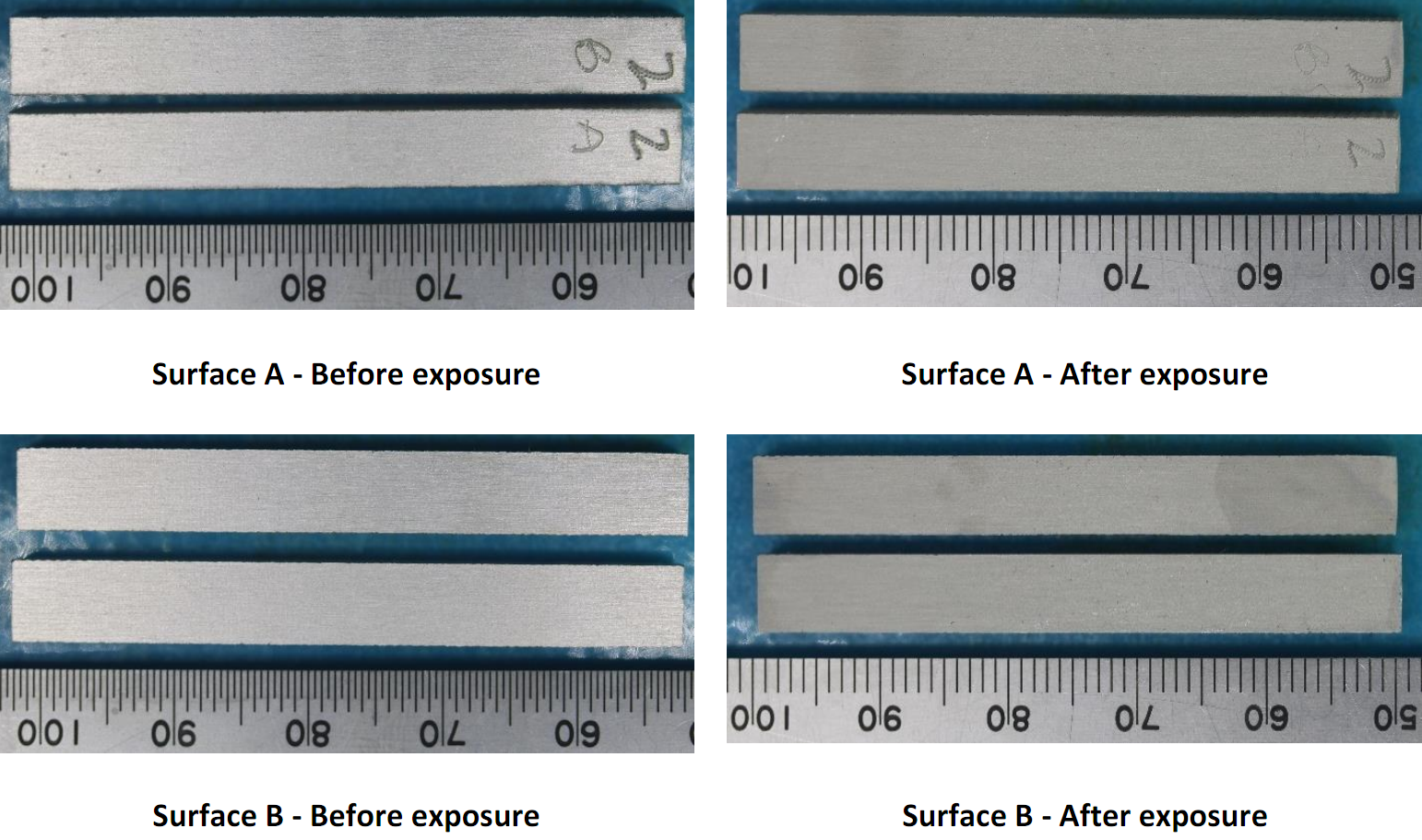

ASTM G67 covers a procedure for constant immersion intergranular corrosion testing of 5XXX series wrought aluminium alloys. In this test, specimens are immersed in concentrated nitric acid at 30°C for 24 h and then the mass loss per unit area is calculated and used as a measure of susceptibility to intergranular corrosion. This test method provides a quantitative measure of the susceptibility to intergranular corrosion of Al-Mg and Al-Mg-Mn alloys.

Although the test method appears to be very easy, maintaining the test temperature at 30°C as per the Standard is a challenge for most labs. Additionally, if all loose particles are not removed during cleaning after exposure, then the mass loss will be low relative to the amount of corrosion that actually occurred. Hence, high precision weighing scale, pre and post-cleaning methods and mass measurement techniques are crucial for the success of this test method.hhhh

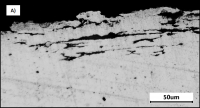

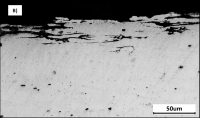

The nitric acid dissolves one of the microconstituents ( βAl-Mg intermetallic compound), in preference to the solid solution of Mg in the aluminium matrix. When this compound is precipitated in a relatively continuous network along grain boundaries, the effect of the preferential attack is to corrode around the grains, causing them to fall away from the specimens. Such dropping out of the grains causes relatively large mass losses of the order of 25 to 75 mg/cm2, whereas, samples of intergranular-resistant materials lose only about 1 to 15 mg/ cm2. When the βAl-Mg compound is randomly distributed, the preferential attack can result in intermediate-mass losses.

A metallographic examination is required in such cases to establish whether or not the loss in mass is the result of an intergranular attack.

Please see our Marine Inspection Services