Pulsed Eddy Current Testing (PEC/PECT)

PEC is a rapid screening corrosion eddy current test method invoving pulses of low frequency eddy currents induced in the test material. Its applications include insulated ferrous pipelines, tanks, vessels and other components. PEC allows corrosion surveys, average thickness and wall loss measurements without removing insulation, cladding, asbestos, fireproofing, concrete or protective coating material from the test surface.

Benefits

- Thickness measurement (Corrosion under Insulation) without insulation removal

- Corrosion assessment of steel embedded in concrete or asphalt

- Corrosion of steel submerged in water (marine conditions)

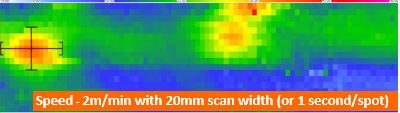

- Fast (2m/min with 20mm scan width or 1 second/spot)

- Accurate (±10%)

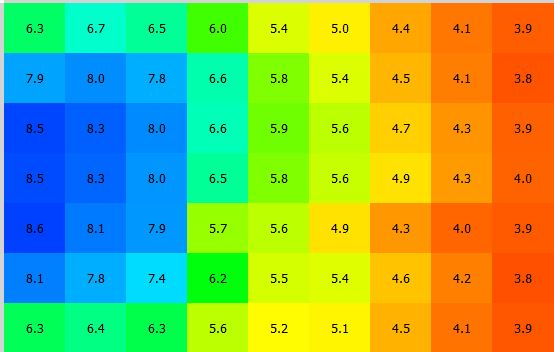

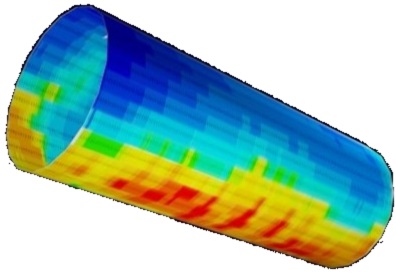

- Digital plan imaging

- Huge cost savings by not removing or reinstating insulation

- No surface preparation needed, saving time and money

- More complete inspections reduce asset downtime

Capabilities

- Hot or cold test surfaces up to 550°C

- Through up to 150mm thick insulation

- Through any non-conductive insulation - natural fibers, asbestos, fireproofing, coatings, ceramic, concrete, brick, foam, wool, thermocol, bitumen, etc

- Through galvanised, stainless, aluminium, cladding or weather jacket

- Through chicken or hog wire reinforced insulation, straps or protective and polymer coating

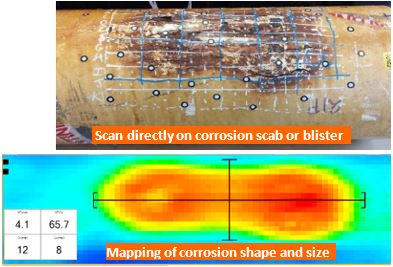

- Through any corrosion scabs, blisters etc. No surface preparation needed, minimising risk and cost.

- Measure thickness from 4 to 65mm on pipes above 75mm diameter or vessels or spheres or support legs.

- No need for scaffolding. Remote control inspection using extension arms up to 4.6m height.

- Battery powered instrument. Perfect for remote locations.

- Absolutely safe. Unlike radiographic methods, involves no X-Ray or Gamma Ray radiation.

- Probes are waterproof for marine applications.

- 30m long telescopic extension arm for measuring underwater. Perfect for piers at ports and bridges.

Corrosion Under Insulation (CUI)

CUI is one of the most undetectable corrosion mechanisms that can affect the integrity of the plant or asset and may not be noticed until the degradation has occurred beyond risk mitigation. Corrosion under insulation CUI, as the name suggests occurs under the insulation layer which is not readily visible to the plant operators. PEC can provide wall thickness measurements through any non-ferrous insulation materials such as natural fibers insulations material, calcium silicate, titanium based coatings, ceramic paint, concrete, brick, foam, wool, thermocol, bitumen, dirt, sludge, etc. It can also measure through galvanised, aluminum and stainless weather sheeting.

A probe sensor is placed on top of the insulation layer. The material covered under the insulation can be kept live and hot up to 550 degrees Celsius. Low frequency pulsed eddy currents are induced in the test material. The duration of sustained eddy currents in the test material is measured and a relative thickness or percentage remaining wall thickness is calculated.

Ideal Applications

- Detection of corrosion under insulation CUI degradation

- Detection of internal flow induced erosion or corrosion

- Wall thickness measurement of tanks or pipe-rack without additional cost of scaffolding work or use of elevated working platforms

- Wall thickness measurement of excavated pipelines without coating removal and without sand blasting or surface grinding.

- Most ideal on insulated, cladded, covered material surface. Subsea and splash zone inspection

- Pulsed Eddy Current - PEC testing on high temperature surface without shutting down plant

- Inaccessible test surface e.g. covered with asbestos or brick wall or sand covered

- Hot or cold insulated pipelines, vessels, equipment, columns, storage tanks, concrete coated sphere legs

- Insulated pipes above 100mm diameter or vessels or spheres

- Pulsed Eddy Current - PEC testing can measure wall thickness from 4 to 65mm with repeatable results within the range of ±10%.

Limitations

- Thickness readings are average thickness under the sensor footprint measured in % remaining wall.

- PECT measures average thickness at the test location (probe footprint) which varies between 35-200mm depending on insulation thickness, clad material and the wall thickness of the test material. Thickness readings are average thickness under the sensor footprint (1.8 times the footprint) measured in % remaining wall.

- Pulsed Eddy Current - PEC testing cannot detect a small isolated pit

- The edge effect impacts PEC measurements when a probe nears geometry variations such as nozzles, flanges, or the end of a structure. Measurements begin to vary from a distance of one Footprint from the center of a probe’s coils.

- Difficult to use on elebows smaller than 200mm diameter

- Current version of software is unable to discriminate near side and far side defects.

- Flaws smaller than the averaging area of the probe will be undersized.

PECT Comparison with other NDT methods

| Characteristics for Comparison | PECT | CRT/DRT | RT (Film based) | UTT |

| Testing without insulation removal | Possible | Possible | Possible | Impossible |

| Use of Radioactive substance | No | Yes | Yes | No |

| Exclusion zone required for testing | No | Yes | Yes | No |

| Testing of large vessels/pipes | Yes | No (Note 2) | No (Note 2) | Yes |

| Testing of operating equipment | Yes | Note 1 | Note 1 | Yes |

| Surface preparation required | No | No | No | Yes |

| Speed of Testing (per m) | Fast | Slow | Very slow | Medium |

| Cost of testing | Economical | Expensive | Expensive | Inexpensive |

| Testing without coating removal | Yes | Yes | Yes | Difficult |

| Testing at elevated temperature | Yes | Yes | Yes | No |

| Testing at sub-zero temperature | Yes | Yes | Yes | Yes |

| Effect of insulation type on results | Negligible | Low | Medium | Not possible |

| Effect of fluid contents | Negligible | High | High | Negligible |

| Probability of corrosion detection | Very High | Very high | Medium | Low |

| “Plan view” mapping of test zone | Very easy | Can be done | Inefficient | Difficult |

| Accuracy of measurements | ±10% | ±10% | ±25% | ±2% |

| Traceability of test results | Very High | high | Medium | Low |

| Repeatability of test results | Very High | high | Medium | Medium |

| Skills required for NDT personnel | Very High | high | Medium | Low |

| Pipes less than 100NB | No | Yes | Yes | Yes |

| Bends in less than 200NB pipes | No | Yes | Yes | Yes |

Notes

-

PEC measures structural (volumetric) wall loss (saturation and decay of eddy current within the steel volume) whereas UT is only localized thickness assessment by measuring time of flight of reflection.

-

Radiographic test results can be non-interpretable due to poor radiographic image on some vessels or pipes due to vibration or flowing fluids or high density fluid contents.

-

Radiographic images may not be obtainable on large diameter vessels or pipes due to the longer distance between radiation source and radiographic capturing devices (film or sensors)

Case Study - Light Poles

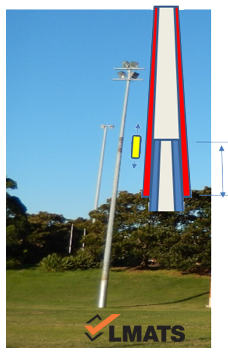

In a somewhat less common application, LMATS employed PEC to measure the sleeve overlap distance in light poles.

In the absence of original drawings or known thickness or tube insertion length, industry end users had specified radiography to measure the length of the steel pole inserted into the structural steel sleeve. Ultrasonic methods were not due to an acoustic gap between the outer and inner steel tubes.

Considering the hazards of radiation and difficulty of creating exclusion zones in public places, LMATS developed a PEC procedure to determine the engagement length of the pole by measuring the combined thickness of the two pipes sections.

Overlapping sections were precisely measured and mapped and a ‘C’ plan view was generated for engineering calculations.

Abbreviations:

- PECT – Pulsed Eddy Current testing using Eddyfi Lyft

- CRT – Computed Radiographic testing

- DRT – Digital Radiographic testing

- RT – Radiographic testing (conventional film based)

- UTT – Ultrasonic thickness test using systematic or unsystematic spot measurements

Frequently Asked Questions

FAQ 1 – Can I measure wall thickness of old bridge structures without removing lead paint?

PEC may be a better option particularly if the coating is not completed adhered to the metal surface and conventional ultrasonic testing is not practical. The international standards and codes require bare metal surfaces for ultrasonic testing.

FAQ 2 – Is PEC useful if there could be pitting corrosion?

PEC cannot detect an isolated pit. But it can detect cluster of pitting. With other methods such as UTT, asset owners nominate to perform random or 100mm grid spacing UTT. Most of the time the probe is twin crystal, 10/2 diameter probe. Hence in a 100x100mm grid, ONLY 0.78% of the surface area is tested. (79mm2 out of 10,000mm2). This means there is 99.2% probability that UTT will not detect an isolated pit or even cluster of pitting in a 100mm grid pattern. Also, UTT depends on the flatness of the back wall. Several published papers indicate that on most occasions, UTT measures incorrect corroded minimum remaining wall thickness because the reflecting surface is either not perpendicular to the compression waves or the sound simply dissipates due to rough surface.

Whereas in PEC, the smallest footprint is 35mm diameter, and because of its speed, 100% of the surface area is scanned without coating removal. Hence, if there is a considerable loss of wall as a result of an isolated pit or a cluster of pits which can affect the fitness for purpose pressure vessel calculations then PEC will 100% indicate volumetric thinning.

FAQ 3 – I have been informed that PEC cannot measure thickness of steel when the surface temperature is 5500C. So how can I apply PEC in my plant?

PEC can measure wall thickness of ferrous steel having surface temperature up to maximum 5500C and adequately insulated so that the surface temperature on the cladding surface is limited to 700C maximum. It should be noted that alternative test method such as conventional ultrasonic testing cannot be performed at such a high temperature.

If the cladding (weather jacket) surface temperature is exceeding 700C then a ceramic shoe can be added at the bottom of the probe and perform PEC. It should be noted that it is not a safer practice to work at such a high temperature.

FAQ 4 – What is the extent of traceability and repeatability of PEC compared with UTT & RT? Is it operator dependent like UT & RT?

UT & RT are highly operator dependent and hence the probability of the traceability of results is uncertain. For PEC, the operator’s involvement is to place the probe on the cladding after the Level 3 has entered all essential parameters. The instrument provides assessment results storing of results, reporting of data, colour pelleting, etc.

FAQ 5 – What is the smallest flaw PEC can detect?

PEC is an average wall loss measuring technique and is ideal for screening and measuring general corrosion through insulation, cladding or other non-conductive coverings. For detection of localised damage such as pitting or cracking, LMATS ’ NDT experts and inspectors can advise on the most appropriate techniques, which may include eddy current array (ECA) testing for detection of linear discontinuities, phased array ultrasonic testing (PAUT) for the detection of small pits and wall thickness, or one of the many other available NDT methods

FAQ 6 – Can I measure the wall thickness of an excavated buried pipeline without removing the coating and grinding on a live pipeline?

While conventional ultrasonic testing requires a prepared or ground flat surface, PEC does not require direct contact. Hence PEC can measure wall thickness on a live pipeline without the need of surface grinding and without the need of coating removal.

FAQ 7 – Can you detect weld locations in an insulated or concrete-encased pipeline?

LMATS can find weld location on your insulated pipe or vessel using PEC. Compared with Radiography, where an exclusion zone and multiple exposures are required, PEC is a single person operation and it can be completed within few minutes on site.

Contact Us

To find out more about LMATS PEC or advanced services contact us on +61 3 9399 9199 or via the form