NFA- Near Field Array - Tube Testing

Near Field Array tube testing or commonly called as NFA is one of the electromagnetic testing method used to detect discontinuities on the internal surface of fin-fan type tubes and ferromagnetic (Carbon steel) heat exchanger tubes.

NFA – Near field Array testing utilizes similar technique as in ECA – Eddy current array testing using an array of coils (up to 30 coils) that activate in sequences. Contrast to the conventional Eddy current testing which employs only bobbin coil, NFA – Near field Array testing utilizes additional tangential coils that assist in obtaining detailed data and discontinuities in all directions. NFA – Near field Array tube testing is the most efficient test method for inspecting Aluminum finned carbon steel tubes. Aluminum finned carbon steel tubes are the most difficult to inspect tubes because the external aluminum fins interferes with the quality of the signals obtained. NFA – Near field Array tube testing can easily detect common discontinuities and discriminate the location and the size of discontinuities such as internal pitting, internal cracks at the tubesheet, internal erosion and the resultant wall loss.

This NFA method is:

Fast, Accurate, Traceable, and Archivable a digital paper trail

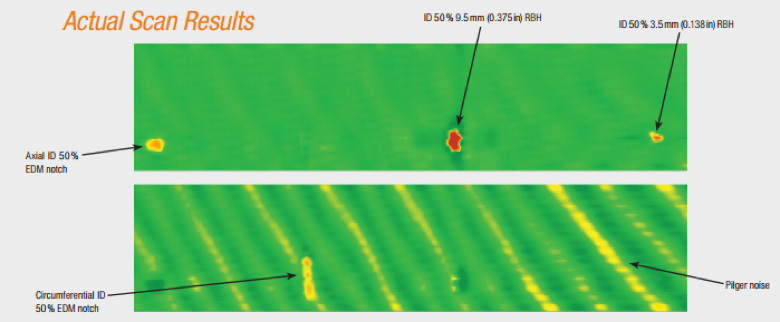

LMATS uses Eddyfi’s software Magnifi for signal analysis and reporting. The software enables NFA – Near field Array tube testing data to be displayed and reported in 2D and 3D ‘C’ scan format that can assist the asset owners to make informed decision on the basis of accurate location of the discontinuity and the precise of the discontinuity.

Ideal Applications:

- Most ideal for efficient and reliable inspection of Aluminum finned tubes and ferromagnetic heat exchangers

- NFA – Near field Array tube testing is ideal for inspecting tubes in the range of 19.05mm to 38.10mm diameter

- NFA – Near field Array tube testing is ideal for detecting internal diameter discontinuities such as pitting, cracks at tube sheet, erosion and wall loss on finned heat exchanger ferromagnetic tubes.

Advantages:

- NFA – Near field Array tube testing can provide 2D and 3D ‘C’ scan images to assist the asset owner to locate exact location of the discontinuity and its precise size

- NFA – Near field Array tube testing can precisely measure volumetric discontinuities of approximately 3mm in a single pass

- NFA – Near field Array tube testing can detect both axial and circumferential cracks

- NFA – Near field Array tube testing can be performed comfortably at 6meters per minutes enabling to reduce downtime of the heat exchanger maintenance

- NFA – Near field Array tube testing does not use magnets and hence the pull speed does not affect the sensitivity s compared to MFL -Magnetic flux leakage technique

- NFA – Near field Array tube testing does not use water (Unlike IRIS – Internal Rotary Inspection System) and hence post cleaning and drying is not required minimizing the risk of water contamination pitting.

Expertise:

Compared to conventional eddy current testing, NFA – Near field Array tube testing instruments and probes are complex and expensive and requires highly trained, skilled and experienced technicians.

LMATS uses Eddyfi Ectane 2 unit for NFA test method.

LMATS professionals are trained and experienced in NFA– Near Field Array Testing method.

See the Heat Exchanger tube testing selector to understand and make informed decision on the type of advanced NDT test method you may need to determine the integrity of your heat exchanger tubes.

LMATS offers (NFA) - Electromagnetic tube testing and inspection using NFT- Near Field Testing system from our Melbourne, Sydney, Brisbane, Albury, Malaysia and India laboratories.

LMATS regularly performs NFA- Near Field Array Testing in VIC -Victoria, NSW - New SouthWales, QLD - Queesnland, QLD - Brisbane, SA - South Australia, TAS - Tasmania, NT -Northern Territory, WA - Western Australia and some of the countries aroung the world.

To find out more about LMATS (NFA) Near Field Array Testing Advanced NDT Tracable Inspection Capabilities simply call us or contact us +61 3 9399 8145 or via the form