MFL Magnetic Flux Leakage - Tube Testing

LMATS offers the latest Advanced Heat Exchanger tube testing and inspection using (MFL) - Magnetic Flux Leakage to assess the integrity of your heat exchange tubes thus maximising production and the life of your heat exchangers. The Advanced Heat Exchanger tube inspection using (MFL) - Magnetic Flux Leakage, offers traceable and archiveable records that enable the following of a "Discontinuity" to a point where maintenamce is required.

Magnetic Flux Leakage tube testing or commonly known as MFL is one of the electromagnetic tube testing method used to detect discontinuities such as corrosion, erosion, pitting and circumferential cracks in finned ferromagnetic and Carbon steel heat exchanger tubes.

This MFL method is:

Fast, Accurate, Traceable, and Archivable a digital paper trail

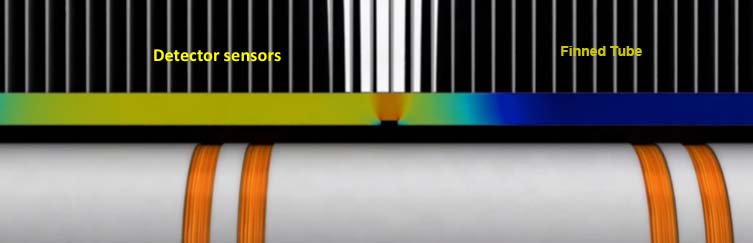

MFL - Magnetic Flux Leakage tube testing technique utilises strong permanent magnets to magnetize conductive tubes, e.g Carbon steel tubes. Magnetic field is induced into the tube material which forms a magnetic circuit between the part and the probe. Magnetic field is induced until the tube material is saturated and it can no longer hold additional magnetic flux. Thus the magnetic flux overflows and the leaking flux is measured using detector sensors placed between the magnetic poles. When discontinuities such as corrosion and material loss are located between the magnets, the magnetic field in the tube material is disturbed and a small amount of flux leaks which is detected by the sensors. The variation of flux leakage induces current in the detector coils that is converted into output signals.

MFL - Magnetic Flux Leakage tube testing probes consists of a magnetic detector placed between the magnetic poles where it can detect magnetic leakage field. Detector sensors then accurately measure the 3 dimensional vector of the leakage field. Magnetic flux leakage is a vector of 3 components and the sensor can measure only in one direction. Hence the MFL - Magnetic Flux Leakage tube testing probes contains a minimum of 3 sensors to accurately measure the axial, radial and the circumferential direction of the signal.

LMATS uses Eddyfi’s software Magnifi for signal analysis and reporting. The software enables MFL - Magnetic Flux Leakage tube testing data to be displayed and reported in presentable format that can assist the asset owners to make informed decision on the basis of accurate location of the discontinuity and the precise of the discontinuity.

Ideal Applications:

- Most ideal for rapid inspection of Aluminum finned tubes and all ferromagnetic heat exchanger tubes

- MFL - Magnetic Flux Leakage tube testing can also be used for normal heat exchanger tubes for diameter above 25mm NB

- MFL - Magnetic Flux Leakage tube testing is ideal for detecting corrosion, erosion, pitting and circumferential cracks

- MFL - Magnetic Flux Leakage tube testing is optimized for internal and external discontinuities.

Advantages:

- MFL - Magnetic Flux Leakage tube testing can detect axial, radial and circumferential discontinuities

- MFL - Magnetic Flux Leakage tube testing has very high sensitivity for pitting and circumferential cracks

- MFL - Magnetic Flux Leakage tube testing is not affected by the presence of Aluminum fins

- MFL - Magnetic Flux Leakage tube testing is relatively high speed inspection technique as compared to other carbon steel tube testing techniques.

Expertise:

Compared to conventional eddy current testing, MFL - Magnetic Flux Leakage tube testing instruments and probes are complex and expensive and requires highly trained, skilled and experienced technicians.

LMATS uses Eddyfi Ectane 2 unit for MFL test method.

LMATS professionals are trained and experienced in MFL - Magnetic Flux Leakage tube testing method.

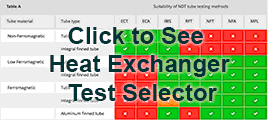

See the Heat Exchanger tube testing selector to understand and make informed decision on the type of advanced NDT test method you may need to determine the integrity of your heat exchanger tubes.

LMATS offers (MFL) - Magnetic Flux Leakage tube testing techniques for inspections of heat exchangers from our Melbourne, Sydney, Brisbane, Albury, Malaysia and India laboratories.

LMATS regularly performs (MFL) - Magnetic Flux Leakage tube testing in VIC -Victoria, NSW - New SouthWales, QLD - Queesnland, QLD - Brisbane, SA - South Australia, TAS - Tasmania, NT -Northern Territory, WA - Western Australia and some of the countries aroung the world.

To find out more about LMATS (MFL) - Magnetic Flux Leakage Advanced NDT Tracable Inspection Capabilities simply call us or contact us +61 3 9399 8145 or via the form