CNC Custom Prototyping WaterJet Cutting

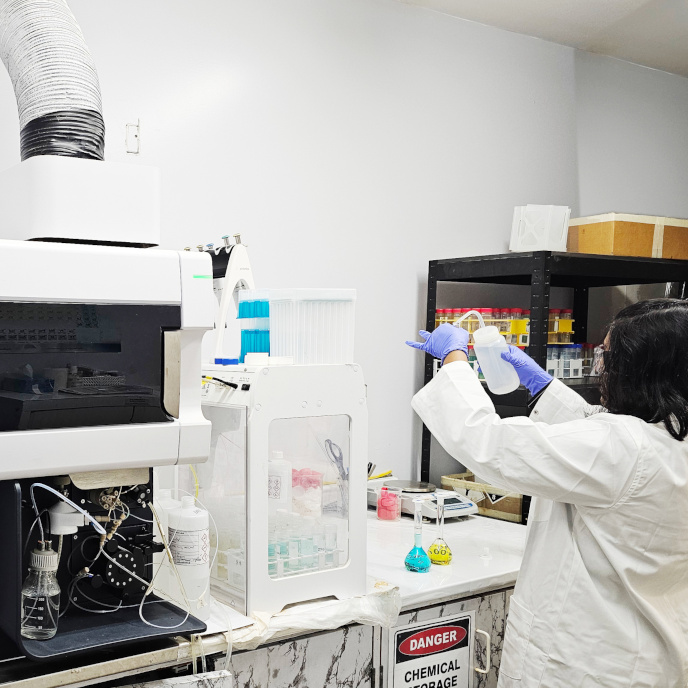

Prototype WaterJet CNC Cutting Service

CNC WaterJet Cutting Carbon fibre sheet

Waterjets quickly cut metal to plastic parts from sheet or pre machined materials using a high-pressure stream of water and abrasive.

LMATS offers a cost-effective 2D CNC waterjet cutting solution whether you need a single part, batch of prototypes, or a production order.

From a simple washer to a complicated design LMATS Custom WaterJet Cutting Prototyping Service has your back.

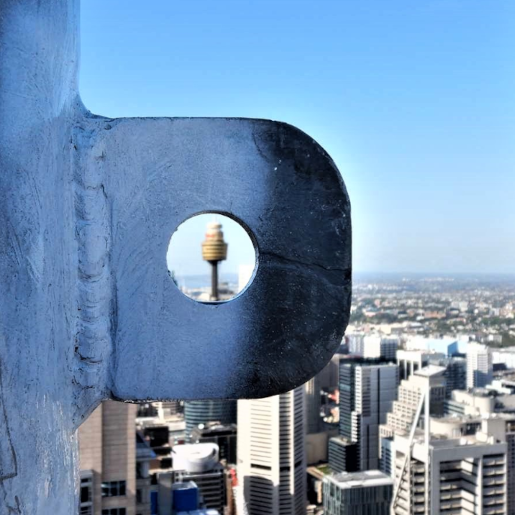

LMATS WaterJet services have the facility to water cut pre machined components.

WaterJet CNC Cutting pre machined components

LMATS CNC WaterJet capacity and accuracy:

- Materials processing, from the hardest and toughest alloys to the softest and fragile, like foams and gasket material and more

- Large cutting deck 1,300 mm x 1,300 mm

-

The LMATS WaterJet Cutter has an Accuracy / Repeatability of 0.0025"[0.064 mm] Linear Straightness ±0.005 in/3 ft [±0.13 mm/m].

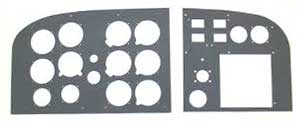

WaterJet cutting of prototype instrument panel

There are five primary reasons to why using LMATS WaterJet services for rapid prototyping service makes sense:

- There is no need to wait for custom tooling

- Inexpensive Method to Gain Highly Accurate Prototypes

- It is an inexpensive way to quickly receive highly accurate prototypes in quantities that make sense for this stage in the development process

- The design can be re prorgammed quickly to adjust the design

- Your Materials can be processed in about 1 day or less.

Advantages of Custom WaterJet Prototyping:

- Tight tolerances achievable outstanding precision and edge quality

- Secondary finishing is generally not required

- Complicated designs are achievable

- Does not cause heat distortion

- Fast turns are possible.

![]()

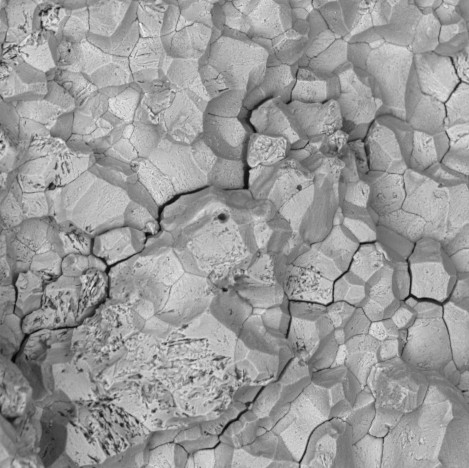

WaterJet cuting of Glass, Stone, Granet, Ceramics and Sintered Silicon Carbide

An outstanding amount of materials can be effectively cut using WaterJet technology

- Sheet metal and plate such as mild steel, stainless steel, aluminum, brass, copper

- Titanium

- Inconel

- Tool Steel

- Glass

- Stone or Ceramics

- Composites like laminated Carbon fiber, kevlar / foam, fibreglass Aliminimum sandwich

- LMATS hair-thin Waterjet quickly cuts gaskets, foams, plastics and thin rubber.

- and more.

WaterJet cut assembled components to show cross sections of assembly.

Industries served by LMATS WaterJet Cutting services

- Aviation

- Defence

- Marine

- Rail

- Mining

- Refining

- Petro Chemical

- Electronics

- Fabrication

- Sheetmetal

- Automotive

- Universities

- Medical

- Roofing

- and more.

See how LMATS use WaterJet Cutting Technology to speed up the inspection and reporting process.

Want to know more about LMATS WaterJet Prototyping and how it can assist you simply call is or contact us through our form