Our Services

With over 600 accredited testing methods and cutting-edge technology.

About LMATS

Leading the Way in Advanced Testing & Inspection

LMATS is an ISO/IEC 17025 and ISO 17020 accredited Australian company delivering over 600 methods of testing, inspection, and assessment across multiple industries.

Established: 2008 in Melbourne

National Presence: 10+ locations across VIC, NSW, QLD, WA

Projects Delivered: 100,000+

Clients Served: 200+ government departments, 3000+ companies

Powered by cloud-based OMS software with Level 3 NDT professionals and engineering qualifications. Your trusted partner for precision testing, sustainability-driven solutions, and real-time insights.

Learn More About Us

Product Quality Inspections are Important, see how LMATS can help you save costs.

Are you receiving what you ordered?

Are you sure that what you are receiving is not counterfeit?

Is the complete shipment of the same quality and meets the specification?

LMATS regularly inspects the following Products

-

Rail Inspections

LMATS provides independent second line checks the manufacturer’s own inspection processes

-

Grinding Media

Ball Mill and Mill Liner Inspections

-

Threaded Fastener Inspections

Bolts, nuts, washers, threaded rod and screws

-

Conductors

used in the high voltage electrical transmission network / grid

Tensile tests, Vickers Hardness tests, Torsion tests, Wrapping test "Ductility", Metallographic tests, Chemical composition, Zinc mass, Grease mass

- Other Products that LMATS Inspect

Structural steel plate and section Inspections

Pipe Inspections

Fittings and flange Inspections

and many more Inspections are available

- Carbon and Sulphur Determination

Product Inspection Services

Avoid Costly Product Defects and Shipment Delays

Product inspections minimize the amount of costly product defects. LMATS Inspections can detect merchandise containing non-standard or non-compliant components.

Identify or Explore Corrective Actions

Inspections help you determine the overall quality of your order, and determine the need to issue corrective actions before any products leave the factory.

Protect Your Company's Brand and Reputation

Sub-standard products result in customer complaints and damage your reputation. Product quality inspections help ensure consistent customer satisfaction.

What Type of Inspections are available from LMATS ?

There are several types of inspections available throughout the production process; First Article [ first off sample ], In-Process and Pre-Shipment inspections. As one of the longest serving inspection companies in Australia and serving world wide clients. As a general guideline, the more uncertain your experience with your supplier the more protection you should use through LMATS product inspections.

What Other Services Are Important to Reduce My Risk?

LMATS has an international reputation for providing independent third-party inspection and testing services.

LMATS is accredited to ISO / IEC 17025 by NATA Australia in the comprehensive range of testing & inspection services.

However our services do not stop with inspection. LMATS can provide you solutions to satisfy your most stringent standards in both destructive and non destructive inspection services of your product or purchase.

Why use LMATS For Your Product Inspections Services

Inspections

LMATS inspects first-article samples prior to volume production. This verifies that product specifications are being met and avoids unnecessary re-engineering or re-work at a later date.

Pre Shipment Inspections

During a pre-shipment inspection, our engineers verify that finished goods conform to your specifications. For example, if an Automotive Product or Auto Part Inspection is required, we would request your specifications and retained samples in advance and use them to ascertain the quality of the products produced by your supplier.

In-Process Inspections

These on-site inspections evaluate samples of your products selected during the manufacturing process. This confirms the quality of your product and allows any necessary changes to be addressed early on, reducing re-work time and costs.

Container Loading Supervision

LMATS ensures that proper methods are employed during product loading, and we verify counts and consistant quality on-site.

LMATS is a Stable company

LMATS is an established and reliable and respected organization, providing quality assurance, engineering and consulting services since 1984.

Global Presence

LMATS offers services in overseas countries and is growing. When services are required in an area where coverage is currently not available, we are able to secure local engineers or arrange travel for our engineers in order to accommodate the request.

Experienced, qualified Multi Disciplined Engineers

LMATS ’s professional and knowledgeable staff represents your interests on-site. Our inspectors and supervisors are qualified engineers. Our staff offers experience in a variety of industries.

Flexible Scheduling

LMATS understands the unpredictable nature of sourcing and the importance of meeting critical deadlines. We schedule accordingly, which often means accommodating last minute requests.

Timely Feedback

LMATS offers online reporting, with detailed reports provided within 24 hours of completion our goal.

Dedicated Account Managers

LMATS employs regional account managers who are available to assist clients.

Scalability

LMATS maintains an advanced HR system that enables a high degree of scalability worldwide. We routinely manage project demand fluctuations within and across countries. We are able to train and deploy engineers within days, for projects of all sizes, so that bookings are completed in the time required.

Product Quality Inspections: LMATS Answer Your Questions

- Ensure the quality is up to specifications when working with overseas and local factories.

- How do you know if you are getting the quality of the product as ordered or is it a discount store quality?

- How can you make sure standards are consistent across the different production runs?

- How do you know that the goods are being handled and packaged properly?

- Is the complete shipment of the same quality and meets the specification?

Product Inspection Services

What is a product inspection?

A product inspection is the assessment of a random sample of an ordered product by an independent company not associated with the manufacturer.

The inspector visits the factory and examines a sample of the order looking for:

- Compliance with the product specifications agreed between the factory and the purchaser.

- Any defects or damage that has occurred in the production process.

- The purpose of this inspection is mainly to ensure that you receive the goods as ordered, in an acceptable condition for the use they are intended.

- The goods will meet a set of specifications and requirements to full-fill their intended purpose.

LMATS has an international reputation for providing independent third-party inspection and testing services.

ILAC MRA recognised ISO 17025 Testing Laboratory However our services do not stop with an inspection. LMATS can provide you with the solutions to satisfy your most stringent standards in both destructive and non-destructive inspection services of your product or purchase.

Why have my products inspected?

Manufacturers do not always follow your instructions in terms of product quality and detail.

- By inspecting the goods before you pay to ship them, you can be sure that you receive what you expected.

- It is far easier to negotiate with manufacturers to fix product defects before they leave the factory and before you have sent the final payment.

- The knowledge that the goods will be inspected can result in the factory taking more care of the product.

- Don’t assume that the final product will exactly match the sample provided beforehand. It is easier to be sure.

What are the different types of product inspection?

There are three main types of product inspection:

- Pre-shipment inspection

- In-production inspection

- Full inspection

- Prior to acceptance on delivery into store

A pre-shipment inspection is where product manufacturing has been completed and the goods are ready to be packed into cartons for shipping. This gives a good indication of the products’ final quality.

In-production inspection is where the product is examined partway through the manufacturing process. This is mainly used when the product is mechanical or similar, and there may be a certain internal piece or process which needs to be checked.

Full inspection is where the entire order is inspected instead of a small sample size like the other two types of inspection. This is good if there is a really high specification or quality level required, or if the product has safety implications and total confidence in it is needed.

Which is the most popular inspection type?

Pre-shipment inspections are a popular choice, they provide a good level of certainty over the final quality. The goods have been fully manufactured and are about to be packed, so they are as complete as possible.

As only a sample of the finished goods is inspected.

Should every order be inspected?

Sometimes businesses will have their first order from a factory inspected, then do away with inspections on subsequent orders. This saves money initially, but assuming that follow-up orders will be of exactly the same quality and standard as the first order can lead to costly mistakes and a lowering of business trust, it can be very expensive.

We highly recommend as a standard procedure every order inspected, even if you have received approved quality products from the manufacturer prior. Factories can often look to expedite costs and lower their production costs thus supplying inferior products on the second or subsequent orders.

Compared to the alternative the inspection cost is an inexpensive way to ensure you are not left with a costly sub-standard order, whether it’s your first time dealing with the supplier or if you have been using them successfully in the past, staff change all the time and so can quality, don't let it be you that pays the price.

What should I ask the inspector to check?

Certified and Reputable inspection companies should have lists for specific types of product they check including:

- Looking for signs of damage

- Checking the product works as it should

- Checking the dimensions of the product

- Check that the product conforms to the standards

- LMATS works with our customers to fine-tune the product inspection procedure to your requirements.

What does a product inspection report contain?

- Inspection reports are comprehensive starting with a description of standard items like the date of inspection, location and factory conditions

- List the products inspected and the defect types found within the sample set. This will normally include both photos of the product from all angles, as well as zoomed-in photos of any defects

- The report will include a pass or fail recommendation, depending on the type of product being inspected purchases should always carefully examine the defects, as sometimes these are not bad enough to fail the order in the inspector’s opinion

- At the end of the inspection process, it is the buyer who needs to decide whether to accept or reject the inspected products

- It is the buyer who has the final say guided by the product inspection report

How many products in the order should be inspected?

- The number of products inspected is dependent on many factors, but in general, inspectors, look to examine around 10%-20% of the order, which is usually a large enough sample size to show up any issues.

- A full inspection includes the entire order, but these take a lot longer and are more expensive. Normally inspecting a sample is enough to show up any areas of concern in the order overall

- In some cases 100% inspection is required due to the sensitivity of the product, ie aviation engine components are 100% inspected.

Why do an in-production inspection?

Especially on a first time order with a new manufacturer, or if the product has a very important part within its manufacturing process, it is sometimes desirable if not mandatory to have it inspected at stages through the production process, any non-conformity issues can be found earlier and rectified before the manufacturing is complete, thus reducing expensive reworks or total losses where the complete batch has to be scrapped.

What to do if the product inspection finds non-conforming issues?

This depends on the non-conformity. If it is minor, you may choose to accept it. If it is major, then you may need to have the supplier fix or replace the faulty products.

- In a replacement scenario, it is always recommended having a second inspection after the non-conformity has been addressed. A second inspection ensures that the supplier does, in fact, fix the issues found. The second inspection should be at the manufacturer’s cost

- There are occasions where product inspections find defects at a level where cancellation of the entire order is the only valid solution

- The key thing is to ensure that the buyer gets what they paid for and that any issues are found before the product is shipped

- There is a significant expense, and potential damage to the buyer’s reputation, if defects are only found when customers start returning the products.

What to do if the manufacturer refuses to make remedy the problems?

Competition for manufacturing is intense, so most factories are very keen to correct any manufacturing issues. They strive to keep the purchaser happy and to receive future orders.

Contracted orders can also set up with protection programs [see trade assistance DEFAT Australia], which may limit payments to the manufacturer until the product has been accepted by the buyer. These also insure against manufacturers not keeping their end of the agreement.

It’s important to have a solid agreement with the manufacturer before the order begins, so both parties know what’s expected and the repercussions if not met.

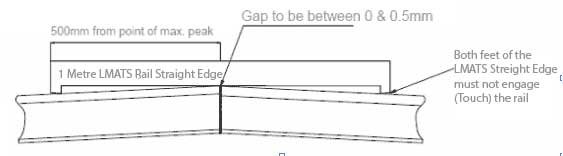

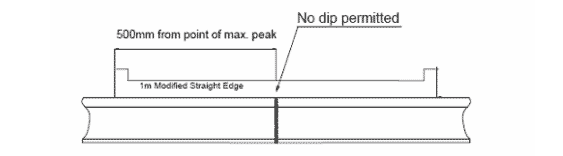

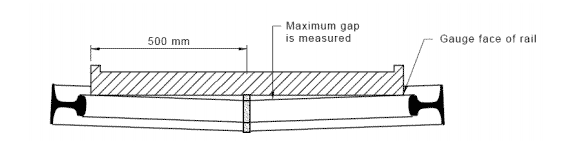

Rail Inspection services

LMATS regularly undertake Rail Weld Joints inspection services using various inspection methods for the inspection of rail flash but welds and Aluminothermic welding "Thermite" procedures.

LMATS has ILAC MRA recognized accreditation pre-shipment inspections a product tested once and accepted everywhere

LMATS provides independent second line checks the manufacturer’s own inspection processes, carried out on either a second or third-party basis. This review not only ensures that the manufacturers are carrying out the correct checks and inspections but witnesses a sample set and identifies additional non-compliances or improvements throughout the process.

In-Service Rail Failures can have catastrophic effects on the bottom line whether it is from derailments causing large production losses to speed restrictions on the rail system

- 10% of joints are Aluminothermic welds

- 90% of joints are Flash Butt welds

- 90% of failures are in Aluminothermic welds

Majority of our work is qualification testing

In addition to inspection for mandatory compliance LMATS have many years of experience in the inspection of quality, finish and customer compliance issues, particularly final customer inspections.

Want to know more about LMATS Rail Inspection Services and how we can assist you. Simply call us or contact us through our form

Metallurgical Examination of Grinding Media Balls

Mill Grinding Media Balls

LMATS provide comprehensive assessment of the structure, hardness and quality of grinding media balls.

LMATS currently perform extensive grinding media testing for a number of major mining operations, both in Australia and overseas Major Mining Operations (end users) and also, the OEM’s (Original Equipment Manufacturers of Grinding Media Balls and Grinding Media Rods).

Grinding media balls form the major portion of the consumable cost of mineral processing plants.

Poor quality grinding balls influence the whole grinding system, including ball consumption, effectiveness of grinding and power consumption thus significantly impacting on the cost of comminution. High wear rates not only increase ball consumption rates but can also impact product quality and, in some cases, increase costs due to increased reagents and/or lower efficiency of downstream processing and extraction.

It is therefore essential that manufacturers have a robust quality control programme (QC) and that end users monitor ball quality and service performance on a regular basis.

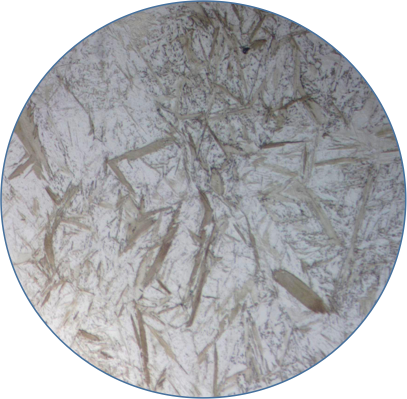

Grinding balls can fail due to inappropriate chemical composition, hardness and microstructure.

Typical failures can include half balls, shelling, capping, surface spalling and misshapen balls. High wear occurs due to incorrect hardness and microstructure.

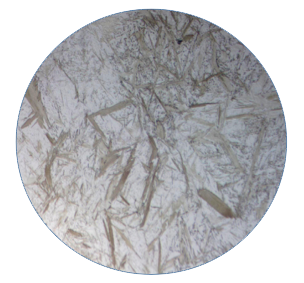

NATA & ILAC Certified testing of grinding ball quality control programmes include the inspection of each shipment to verify correct supply, and statistical sampling for further testing. A typical test programme will include visual inspection, hardness testing at the surface and through thickness profile, chemical analysis, macro and microstructural examination. These control programmes can be tailored to suit individual customer requirements as required.

| Tests | Parameter(s) monitored |

| Visual inspection: | Ball shape, surface finish, grooves and folds, flaws. |

| Hardness Testing: | Hardness level which is related to wear performance. This is the basic QC test adopted by the ball supplier. |

| Average volumetric hardness determined from a hardness traverse. | Indicates wear performance, residual stress level. Typically performed at 2 mm spacing commencing 1 mm from surface, rather than at 5 locations, giving an accurate hardness profile. |

| Macrostructure: | Segregation, cracking, folds, extent of hardening. |

| Microstructure: | Assess level of martensite, bainite, pearlite and austenite to assess the degree of transformation (related to toughness and hardness and therefore wear performance). |

| Chemical Analysis: | Full chemical analysis including trace elements assesses the grade of steel or cast iron used. Enables parameters such as hardenability or % carbides to be calculated. LMATS utilise PMI and Optical Emission Spectroscopy (OES) |

| Gas analysis: | (H, N, O) Gas analysis test for Nitrogen, Oxygen and Hydrogen content in the steel. If there is elevated amounts of these gasses it can result in cracking and spalling of the grinding media balls. |

This information will directly assist your production staff to:

• Monitor the expected life of grinding media during grinding operations to enable informed decisions regarding mill performance.

• Ensure that only consistent quality grinding balls are used, thus reducing the expense of either fast wearing balls requiring additional media or the fracture of over-hard media resulting in loss of mill efficiency.

In addition investigation of ball failures and examination of scats should also be conducted to understand the failure and wear mechanisms in order to improve on grinding ball performance.

The main quality control criteria to minimize premature failure will be discussed as well as examples of failures and causes.

The object of routine testing of grinding balls is to provide an indication of the quality of the balls being used or considered. Variations in the parameters monitored can be evaluated in conjunction with the performance of the grinding circuit.

This gives confidence that any milling issues are not media related or enables corrective action to be discussed with the supplier.

Internal tests are performed on a water jet cut surface, ensuring avoidance of thermal alteration that can occur if friction or wire ( spark erosion EDM ) cutting is used.

The water jet cutting method used on grinding media is also cost effective.

Advanced testing techniques such as residual stress measurement, evaluation of steel segregation or steel hydrogen levels are available.

Investigation of ball failures and material issues are performed. Mill liners and other components can also be investigated or advice provided.

Grinding Media Analysis

Mill Grinding media ball quality is central to efficient and cost-effective comminution of a mill operation.

Comminution costs are mainly electricity, grinding balls and liners. Of these three components, grinding balls form the major portion of the consumable costs, and can be as high as 40%–45% of the total.

LMATS offer a fully independent ILAC accredited Grinding Media Quality Analysis Services to test all incoming batches of Grinding Media Ball and Mill Liners thus ensuring you are receiving what you ordered.

Poor quality grinding balls influence the whole grinding system, including ball consumption, effectiveness of grinding and power consumption; thus significantly impacting on the cost of comminution.

LMATS is ILAC accredited The International acceptance of technical test and calibration data for exported goods resulting in "a product tested once, and accepted everywhere".

LMATS Grinding Media Analysis Services Pre Shipment inspection.

By using LMATS for grinding media pre shipment inspections to check that the Mill Grinding Balls are meeting the specification for hardness, shape, microstructure and chemical analysis the approval for shipping can be given.

A landing shipment inspection of your grinding media using LMATS will confirm if the samples are meeting the same specification as the pre shipment analysis thus the customer can make an informed decision to either accept or reject the shipment.

Using LMATS to closely monitor each shipment is the most reliable method of guaranteeing continuous high quality of your grinding media. For minimal cost, you can be sure you are receiving the quality you’re paying for.

LMATS regularly undertake Comprehensive Testing on Mill Grinding Media - Balls, Mill liners and Mill lifters for:

• Defects

• Shape

• Hardness Testing

• Microstructure

• Chemical analysis

LMATS also perform failure analysis of mill components, liners and lifters

• Mill Liners

• Mill Lifters

• Mill Rotors

• Mill Bearings

• Primary and secondary Crushers

LMATS offer a full and comprehensive range of Mechanical testing and Metallurgical Services.