Failure investigation on coatings - Protective Coating Failure Analysis

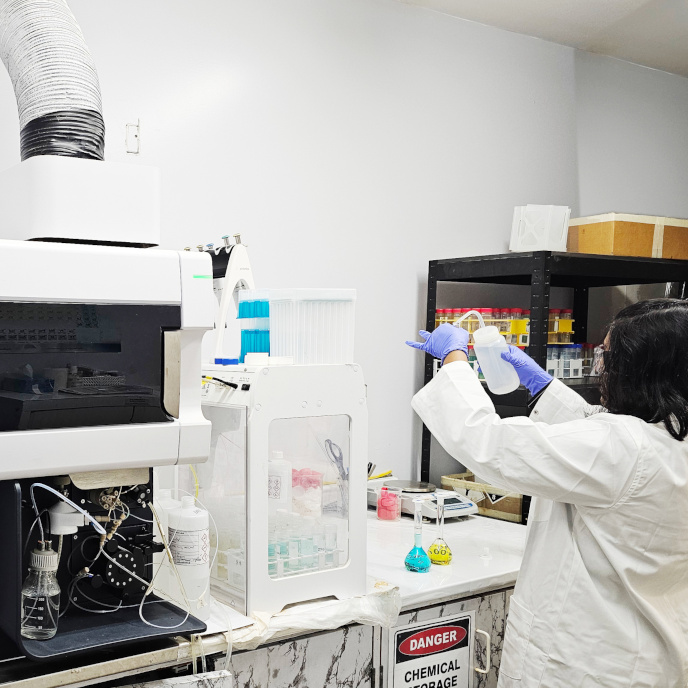

At LMATS Our NACE Certified staff is experienced in industrial, commercial, architectural and institutional coating inspection, design and project management throughout the world, and we invite you to put those vast experiences to work for you.

LMATS Professional Services include Forensic Failure investigation Independent Expert Witness Level 3 Services for NDT

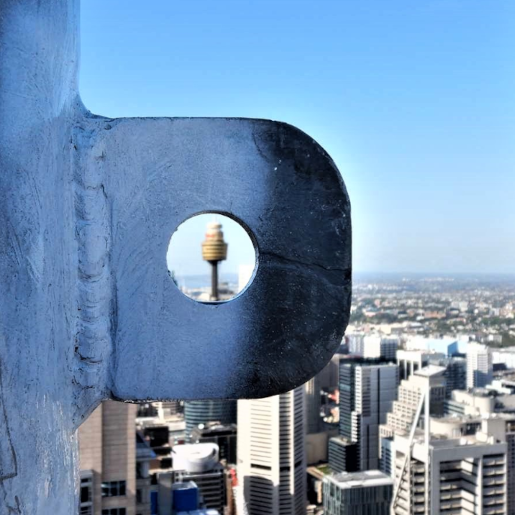

To investigate a failure, and analyze the conditions that promoted the failure, important information must be collected on the failed coating. Background information on the coating type and application procedure, the service history and environment, and physical evidence of the failed coating are necessary to determine why, how, when, and where a failure may have occurred.

If these answers are provided during the course of the investigation, future failures may be better understood or possibly prevented.

FAILURE ANALYSIS

A coating failure analysis investigation is much like the work of a detective. Clues or relevant facts related to the investigation must be gathered, analyzed, explored, and studied to make an informed determination.

Failure Analysis – Sequence of Events recorded

Justification for conducting a coating failure analysis investigations is the most important issue for a failure analyst.

Corrosion protection, aesthetic, production, or litigation related purposes provide excellent examples for justification.

Collection of all Background Data associated with the Failour.

Sample Removal

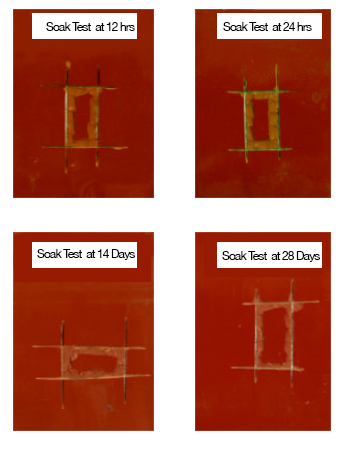

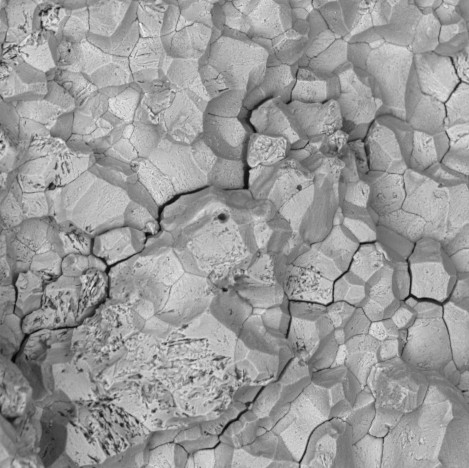

The decision to remove a sample specimen of a paint or coating, or of the underlying substrate, is a very important part of the failure analysis investigation. Sample selected should be characteristic of the coating and/or substrate and contain a representation of the failure or corrosion attack. For comparative purposes, a sample of the intact coating and/or substrate should be taken from a sound and normal section. In conjunction, for a complete microscopic and chemical evaluation and analysis, samples from the failure, adjacent to the failure, and away from the failure are necessary.

COATING FAILURES

The majority of coating-related failures can be attributed to six primary causes. These causes are as follows.

- Improper surface preparation – the substrate surface is not adequately prepared for the coating that is to be applied. This may include cleaning, chemical pretreatment or surface roughening.

- Improper coating selection – either the paint or coating selected is not suitable for the intended service environment, or it is not compatible with the substrate surface.

- Improper application – this can be a problem with either shop-applied or field applied coatings, and occurs when the required specifications or parameters for the application are not met.

- Improper drying, curing and over coating times – again, this problem relates to a lack of conformance to the required specifications or parameters.

- Lack of protection against water and aqueous systems – this is a particularly serious problem with aqueous systems containing corrosive compounds such as chlorides.

- Mechanical damage – which results from improper handling of the painted or coated substrate, resulting in a breach in the paint or coating.

- There are innumerable possible failure modes which can result from these primary causes.

Failure modes will be divided into three general categories:

Formulation-related failures.

Substrate-related failures.

Physical defect-related failures, including blistering.