What is FTIR?

Fourier Transform Infrared spectroscopy or FTIR spectroscopy is known as an acute and meticulous analytical technique specifically for detecting or pinpointing organic compounds in polymeric and composite materials. Moreover, probing different types of chemical bonds makes FTIR capable of detecting inorganic materials. Quantitative analysis of organic materials in different compounds is another highlighted feature of FTIR spectroscopy.

The operation principle of FTIR is based on the interference of infrared (IR) rays and the molecular structure of the target specimen. The adsorption of the incident rays by specimen molecules causes them to vibrate or rotate at a specific frequency. The resulting wavelength of these vibrations or rotations can be recorded as a spectrum determining the sample's molecular structure.

LMATS offers FTIR spectroscopy to a wide range of industries in different fields, such as environment, food, forensics, pharmaceuticals, polymers, plastics, rubbers, and polymer-based composites, to name a few.

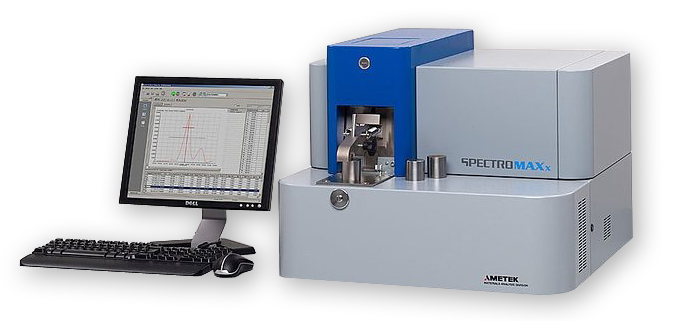

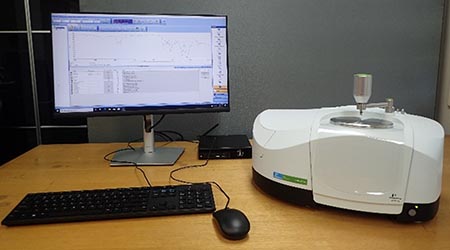

FTIR Spectroscopy Testing Equipment

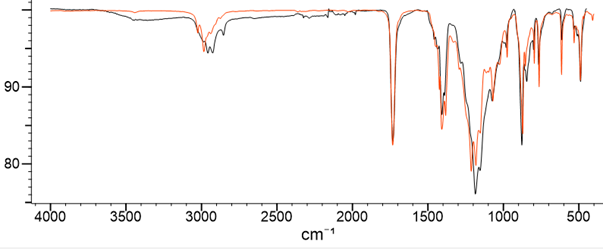

FTIR Spectroscopy Testing Equipment  Sample Result:

Sample Result:

Standard Poly(vinylidene fluoride) + Poly(ethyl acrylate) 4:1 blend

FTIR applications:

FTIR spectroscopy is used in organic synthesis, polymer science, petrochemical engineering, pharmaceutical industry, and food analysis. In other words, it has a wide array of applications including:

- Identification of compounds such as polymers, compounded plastics, blends, fillers, paints, rubbers, coatings, resins, adhesives, epoxies, lubricants, fuels, oil coatings, and fabrics

- Quality control of incoming and outgoing materials

- Identification of contaminants based on microanalysis of materials

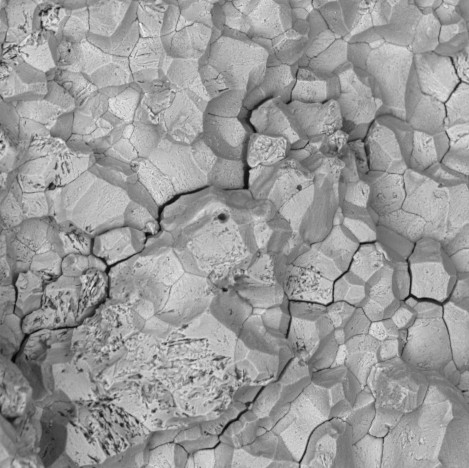

- Analysing thin films and coatings on the surfaces

- Identification of oxidation, decomposition, or uncured monomers in failure analysis investigations

FTIR Advantages:

- Fast and easy analytical technique (providing answers within seconds)

- Minimal or no sample preparation, no consumables

- Suitable for a small amount of sample (for example one drop of liquids)

- Excellent sample-to-sample reproducibility

- Minimal operator-induced variations

FTIR limitations:

- Not suitable for elements, simple ionic compounds, and purely ionic acids in water

- Limit of detection ~0.1 wt% for routine analysis