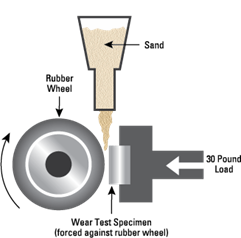

Dry Sand Abrasion Test (ASTM G65)

Dry Sand Abrasion Test method is used to test the abrasive resistance of metals, composites, ceramics, weld overlays, and thermal spray coatings used in applications such as mining equipment, conveyor systems, and components exposed to abrasive environments. . Abrasion testing can provide data on material resistance under laboratory controlled conditions.

The process involves rubbing the samples specimen surface with the help of the rubber wheel with certain force applied and a continous flow of dry silica sand flowing at the interface.