In order to guarantee the acceptable ferrite content in the final product, ferrite measurements are performed on the actual product using Fisher ferritoscope MP30C. Ferrite measurement using Fisher Ferritoscope is a non-destructive test method which assures the quality of the product without the need of expensive laboratory based destructive test methods. The test is performed in accordance with the manufacturer's instructions, EXXON Mobil, ESSO Shell specification and laboratory based validated methods. Experienced Metallurgist, Engineers and Technologist at LMATS provides accurate and reliable ferrite measurement on-site and in-situ products.

In order to guarantee the acceptable ferrite content in the final product, ferrite measurements are performed on the actual product using Fisher ferritoscope MP30C. Ferrite measurement using Fisher Ferritoscope is a non-destructive test method which assures the quality of the product without the need of expensive laboratory based destructive test methods. The test is performed in accordance with the manufacturer's instructions, EXXON Mobil, ESSO Shell specification and laboratory based validated methods. Experienced Metallurgist, Engineers and Technologist at LMATS provides accurate and reliable ferrite measurement on-site and in-situ products.

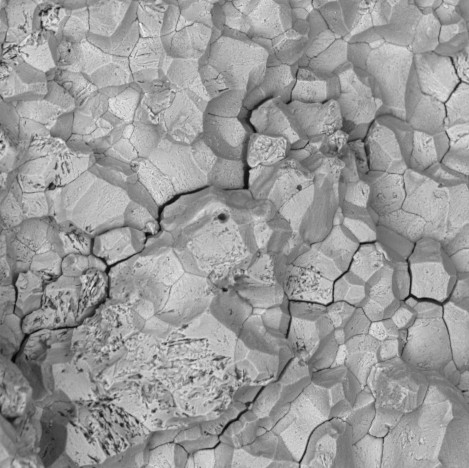

Metallographic techniques that allow simple differentiation between morphologically similar inclusions are briefly discussed. While the methods are primarily intended for rating inclusions, constituents such as carbides, nitrides, carbonitrides, borides, and intermetallic phases may be rated using some of the microscopic methods.

LMATS is NATA accredited to perform inclusion contents analysis in accordance with AS 2087 – macro test method and AS 2197 – micro test method.

LMATS provides report along with a JPEG image of the microstructure to their clients.

Simply request LMATS ’ supportive staff and they will assist you to complete your task in time.

Simply request LMATS ’ supportive staff and they will assist you to complete your task in time.

LMATS is NATA accredited to perform grain size analysis in accordance with AS 1733 and ASTM E112.

LMATS provides report along with a JPEG image of the microstructure to their clients.

Simply request LMATS ’ supportive staff and they will assist you to complete your task in time.

The Graphite Classification Test method covers the classification of graphite in cast irons in terms of type, distribution, and size. This test method is intended to be applicable for all iron-carbon alloys containing graphite particles, and may be applied to gray irons, malleable irons, and the ductile (nodular) irons

LMATS is NATA accredited to perform graphite classification in accordance with AS 5049 and ISO 945.

This test method is used to designate graphite microstructure in cast irons.

More Articles ...

LMATS Services

LMATS advanced testing and inspection services include:

-

Advanced NDT - ECA Eddy Current Array test

-

Advanced NDT - PAUT Phased Array Ultrasonic test

-

Advanced NDT - TOFD Time of Flight Diffraction

-

Advanced NDT - LRUT Long Range Ultrasonics

-

NDT - Non-destructive testing - RT, UT, ET, MT, PT

-

Coatings Inspection - NACE

-

Risk Based Inspection (RBI)

-

Pressure Vessel Inspection (PVI) - AICIP & Conformity

-

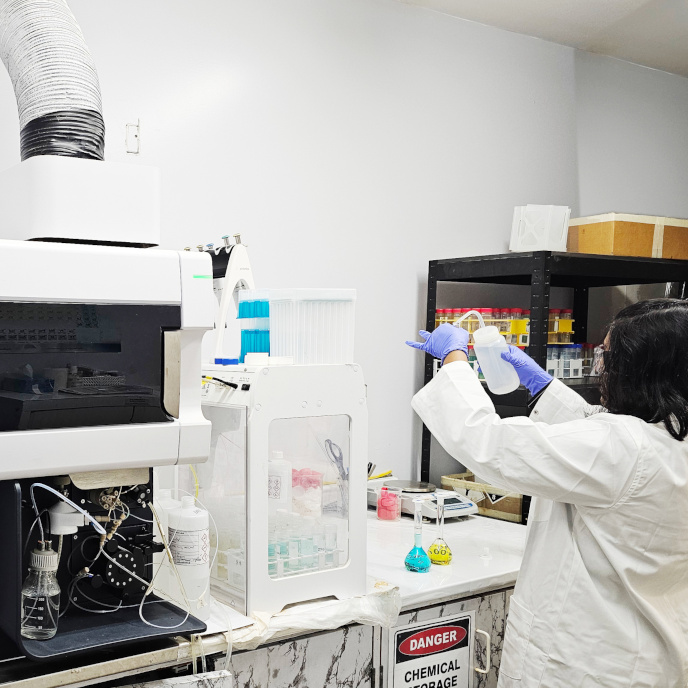

Chemical Analysis

-

Third party Inspection & expert Witness

-

Quality Audit & NDT Level 3 services

-

Hydrostatic Pressure Testing

-

PMI - Positive Material Identification (XRF)

-

Weld (WPS / WPQR) Qualification

-

Mechanical Testing

-

Corrosion Resistance Testing

-

Metallurgical Services

-

Failure Investigation

-

Concrete Testing