Meet LMATS Board of Directors.

David Buchanan GAICD, BMet

Non-Executive Chair

David Buchanan is a seasoned executive with over 30 years of extensive experience in the steel industry, holding leadership positions in prominent international corporations. He has been the CEO of the Australian Steel Association (ASA) since June 2020. David is a graduate of the Australian Institute of Company Directors and Ballarat University, where he earned a degree in Metallurgy.

David is actively involved in industry advancements, recently being appointed to the ITRF subcommittee focused on improving Australia’s anti-dumping system. He also serves as the CEO of the Advanced Fibre Cluster Geelong, where he continues to drive innovation and strategic growth.

David Buchanan’s extensive experience and leadership in the steel industry make him a pivotal figure in driving strategic initiatives and fostering industry growth.

Eric Kreutzer BSc

Non-Executive Director

Eric has over 40 years’ experience in the mining and technical consulting industries, including senior management of mining operations (exploration, mining and extraction and minerals processing) and consulting companies (engineering, asset integrity and asset management).

Eric’s consulting clients have included state and federal government authorities (Commonwealth, NSW, Qld, SA), multinational mining companies (BHP, Glencore, Anglo American) and multinational oil and gas companies (Exxon Mobil, Caltex, BP, Shell) and public and private utilities (MacGen, CS Energy, Origin, AGL, Energy Australia) in the power generation, mining, water and ports sectors. Work experience includes general management, project management, market and business development and natural resource definition and extraction programs. He has extensive experience in the management of multifaceted heavy industry projects for both naturally occurring and manufactured assets including mines, power generation facilities, transport infrastructure - (bridges, roads tunnels and rail), dams, pipelines, ports and wharves.

Rajesh Katwe

Executive Director

Rajesh is a seasoned industry professional with over 18 years of expertise. Having started with LMATS as a technician in 2008, Rajesh rose to operations manager in 2013 and to director in 2022. He consistently supported LMATS ' long-term vision through business development, operational efficiencies, strategic growth, and acquisitions. A toolmaker by trade, Rajesh’s technical and leadership capabilities cover LMATS capabilities from both conventional and advanced Non-Destructive Testing (NDT) to materials testing and qualification. With his comprehensive understanding of the business, ability to navigate complex challenges, foster innovation, and build strong client relationships, Rajesh has been instrumental in positioning LMATS as an industry leader.

George Farah GAICD, BEng(Mat)

Managing Director

George is an engineer, executive, and leader with over 15 years of expertise. As Managing Director since 2023, George oversees operations with a focus on leadership, culture and organisational growth. His technical expertise spans failure investigations, condition assessments, metallurgical analysis, compliance testing, corrosion, remediation and construction project management. A Graduate of the Australian Institute of Company Directors (GAICD) and Registered Professional Engineer (VIC), George brings a strong understanding of corporate governance, strategic decision-making, and risk management, complemented by his ability to foster collaboration and drive sustainable business outcomes.

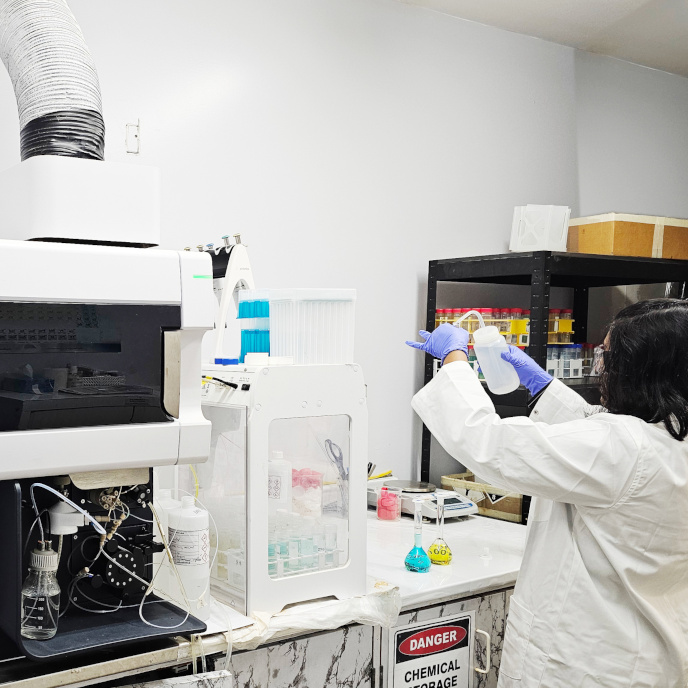

We use an Omax© Water Jet Cutting machine for sample preparation.

We use an Omax© Water Jet Cutting machine for sample preparation.