Metallurgical Services and Consulting

LMATS provides metallurgical consulting services in physical and production metallurgical sector. This involves assessment of chemical, physical and mechanical properties of material for alloy or grade identification or for failure investigation by performing chemical analysis (OES & XRF), mechanical testing, metallography and several chemical tests. We also provide materials and engineering consultation and advice, as well as failure and root cause investigation.

Metallography

Metallography is one of the metallurgical practices to study microstructure of material either by microscopy or macroscopy. Most of the features required for general engineering purpose are resolved in optical microscopy. Scanning Electron microscopy and Transmission electron microscopy are advanced methods of metallography which are applied when the microstructure cannot be resolved at less than 1000x or when loking for a specific microconstituent or a feature.

How Metallography is Performed

Metallography involves systematic sample preparation commencing from specimen extraction to final etching. The test specimens are extracted from the product or sample by cold cutting to prevent change in the microstructure from normal cutting. Occasionally, small specimens are mounted (hot or cold mounting) in phenolic or epoxy resins or bakelite. Test specimens are ground in stages commencing from coarse grained abrasives to fine grained followed by final polishing using diamond paste. Typical final polishing is performed using 1 micron diamond paste. Depending on the requirements, the test specimens are chemically etched to react with selective micro constituents which aids in discriminating each type of micro constituents.

Purposes of Metallography

Metallography can determine the quality of material in terms of hardness, strength, toughness, fatigue behaviour, corrosion resistance and heat treatment condition. Scanning Electron Microscopy (SEM) can reveal further details at microconstituents level.

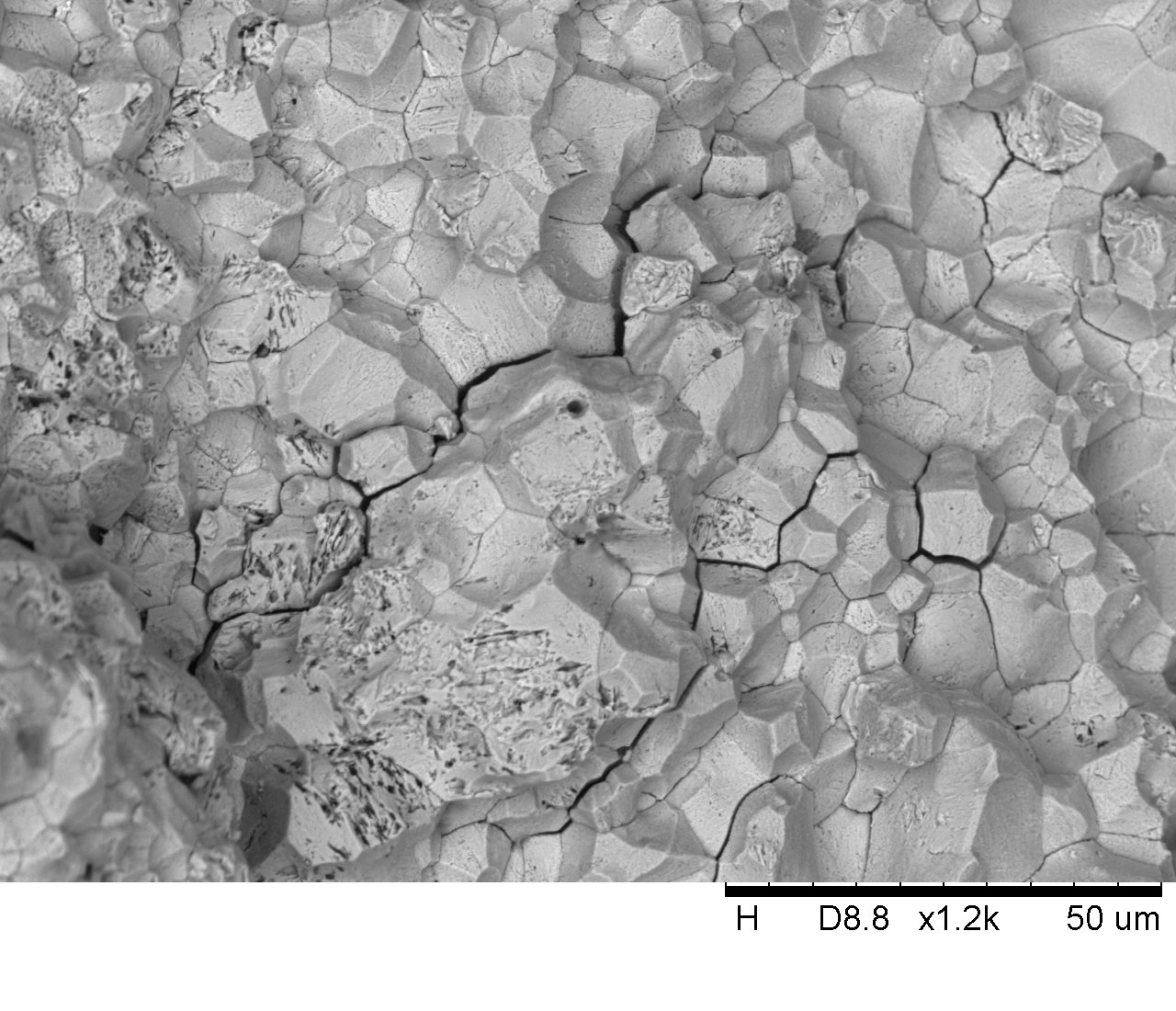

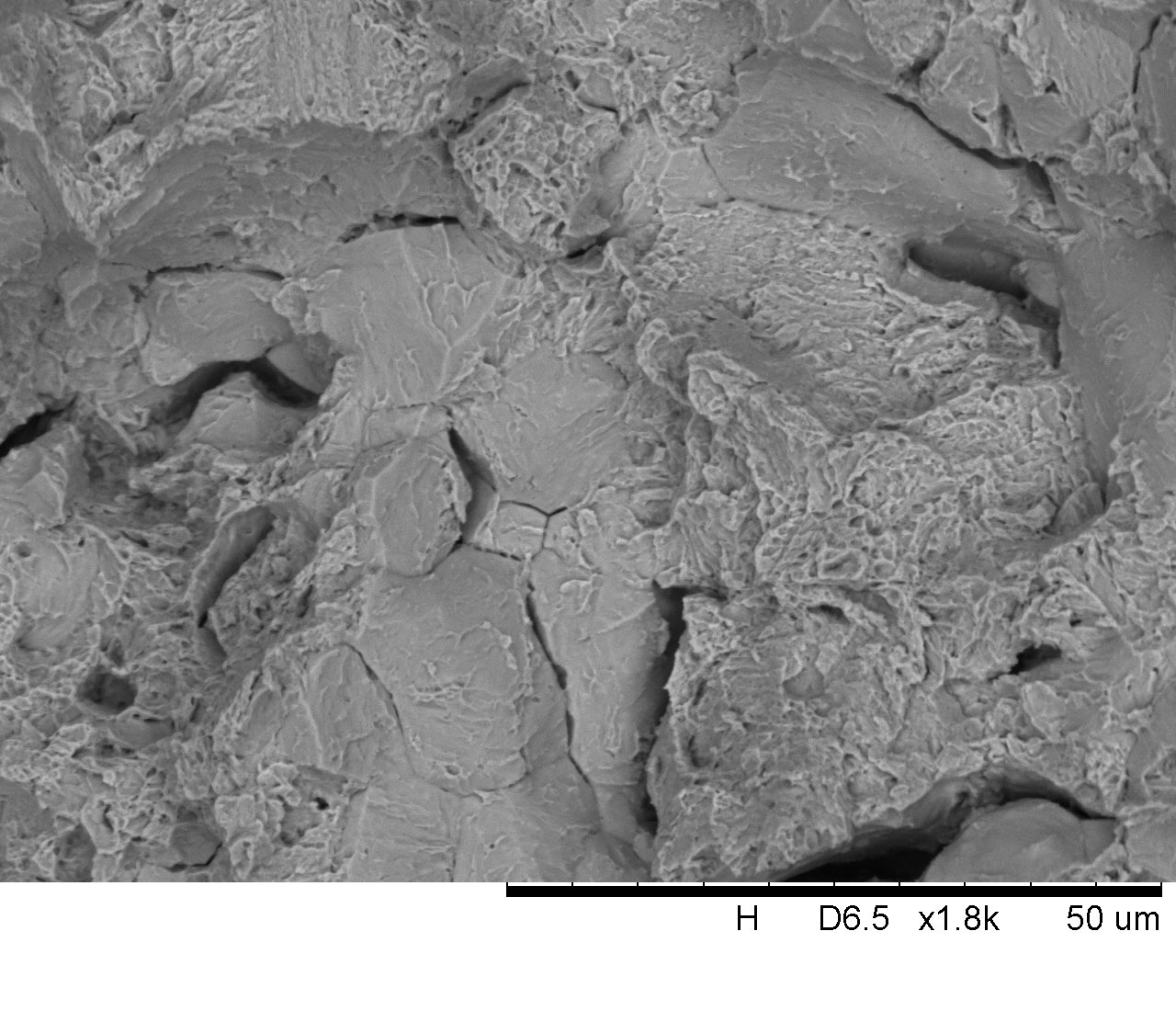

Prepared specimens are examined under optical microscope or low magnification stereoscope or scanning electron microscope to reveal and interpret the microstructure. Microscopy is also performed on actual products without destroying the product or diminishing the further use of the product. Replication of the microstructure allows this examination to be competed in-situ while the component is in-service. The following micrcograph is an example of hydrogen embrittlement identified by LMATS engineers.

Macrographic Examination

Macro tests or macro examination is performed on the cross section, longitudinal section or 'Z' direction ( through thickness) as an independent test to evaluate subsurface conditions or as an subsequent step of another test to reveal the effects on the subsurface.

Generally macro test or examination is performed at less than 10x magnification. Several semi-finished and samples of finished products are subjected to macro test to reveal internal discontinuities such as impurities, inclusions in rolled products or grain flow in forgings after exposure to appropriate preparation and exposure to chemicals or heat.

Macro test is also performed on the test specimens exposed to other tests such corrosion resistance test, passivation, salt spray test, case depth measurement.

The most common test is weld cross section examination to reveal internal discontinuities, weld profile, weld passes and sequence, extent of penetration and the quality of weld.

LMATS performs weld macro examination to satisfy the requirements of huge fabrication industry in Australia.

LMATS performs macro examination in accordance with AS 2205.5, ASME IX QW 183, QW 184, EN 1321, AS 1554, AS 3992, AS 2885.2 and similar national and international standards.